Microstructure Facility

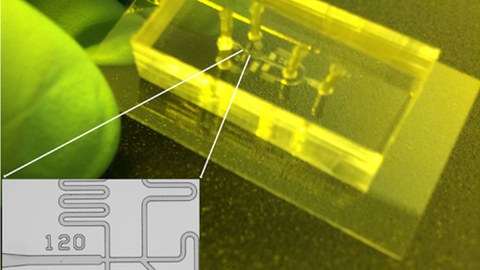

The Microstructure Facility provides cutting edge technologies for micro-structuring of organic/inorganic materials offering skills and capabilities within photolithography, soft lithography, polymer microstructuring, thin film deposition, 3D printing and microfluidics. We produce SU-8 master molds, PDMS microfluidic chips, micro-contact printing stamps, microelectrode arrays, customized cell culture plates and many other related things. We provide our services not only for TU Dresden affiliated customers but also for external institutions.

Welcome

If you need microstructures for your research or buisiness project we will be happy to help you to produce them. Photolithography, metal deposition, soft lithography, 3D printing and many other thechnologies are avaliable here for you. Even if you are not completly sure what exactly you need do not hesitate to contact us. We can always disscuss possibilities and give you an advice.